Unlocking Efficiency: The Importance of China Lathe Machine CNC Turning Parts

In the world of manufacturing, precision and quality are paramount. China lathe machine CNC turning parts play a crucial role in ensuring that machinery operates smoothly and efficiently. These components are the backbone of various industrial applications, enabling manufacturers to produce goods with the highest standards. In this article, we will delve into the advantages of utilizing CNC turning parts from China and explore how businesses can leverage these benefits to achieve operational excellence.

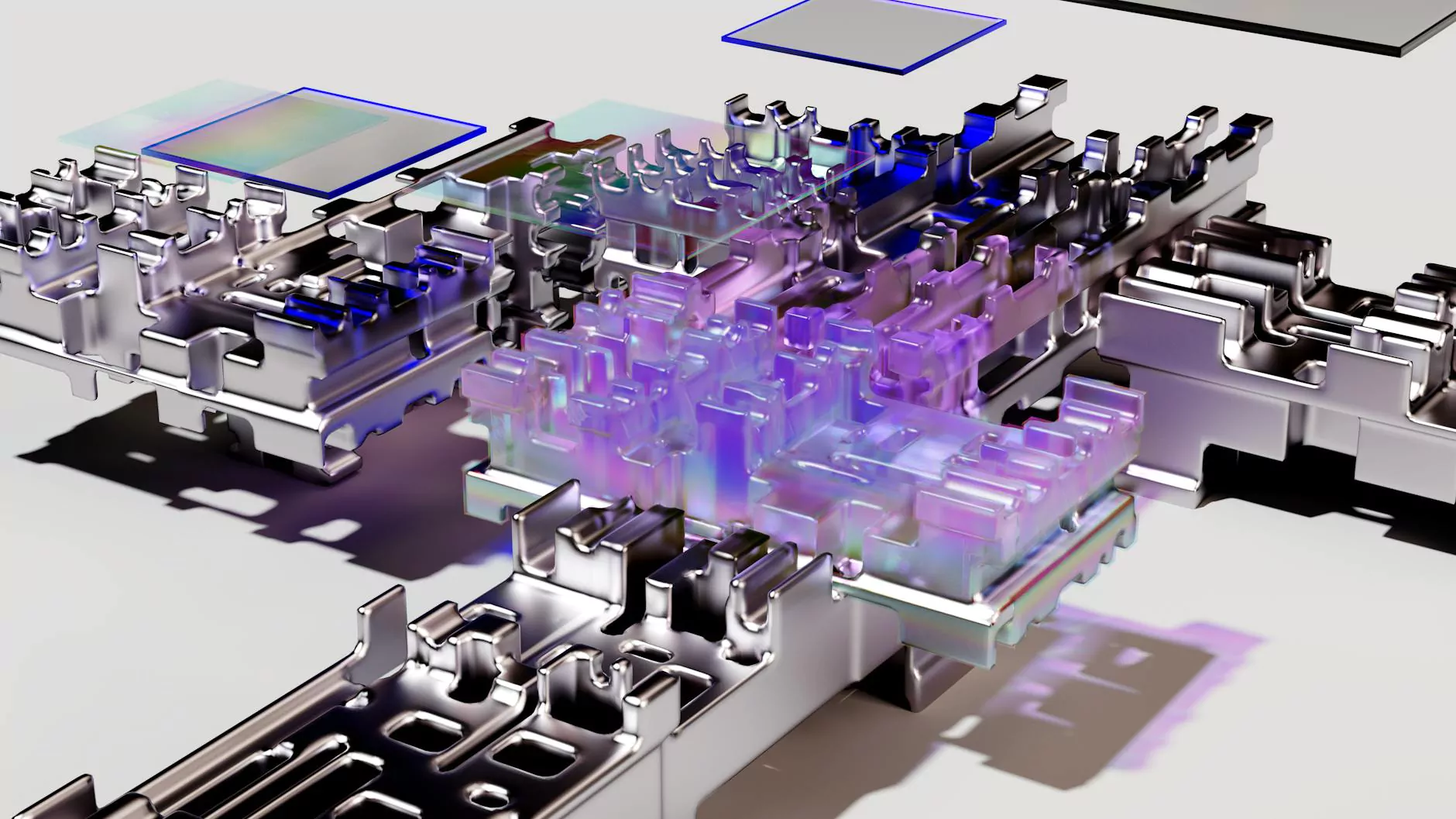

The Rise of CNC Machining in Metal Fabrication

CNC (Computer Numerical Control) machining represents a transformative shift in the manufacturing landscape. This technology allows for the automation of machine tools, providing unmatched precision and repeatability. As industries evolve, the demand for high-quality china lathe machine CNC turning parts has surged, thanks to several factors:

- Increased Production Efficiency: CNC machining drastically reduces production times, allowing companies to fulfill orders quicker and more effectively.

- Enhanced Precision: The use of CNC machines guarantees a level of accuracy that manual machining simply cannot match.

- Cost-Effectiveness: With economies of scale, sourcing CNC turning parts from China often proves to be a more affordable option without sacrificing quality.

Exploring the Benefits of Sourcing CNC Turning Parts from China

When considering suppliers for china lathe machine CNC turning parts, it’s essential to understand the advantages that Chinese manufacturers offer. Here are some notable benefits:

1. Competitive Pricing

Chinese manufacturers are renowned for their ability to produce goods at lower costs. This pricing advantage is influenced by a combination of factors, including lower labor costs and advanced manufacturing technologies.

2. High-Quality Standards

Many reputable China-based manufacturers adhere to international quality standards like ISO 9001, ensuring that their products meet global requirements.

3. Versatility and Customization

China's vast manufacturing capabilities enable firms to request highly customized china lathe machine CNC turning parts tailored to their specific needs, allowing for greater versatility in production.

Key Considerations When Choosing CNC Turning Parts Suppliers

While the benefits of sourcing from China are evident, selecting the right supplier is vital. Here are some key factors to consider:

- Experience and Reputation: Consider suppliers with a proven track record in the industry and positive customer reviews.

- Quality Assurance Processes: Inquire about the quality control measures the supplier has in place to maintain high standards.

- Technical Support: Choose suppliers that offer robust technical support to assist with any issues or customization requests.

- Lead Times: Understand the manufacturing and shipping timelines to ensure that your production schedules are met.

Applications of CNC Turning Parts in Various Industries

China lathe machine CNC turning parts are utilized across a multitude of industries, showcasing their versatility and essential role in manufacturing. Here are a few sectors where these parts are indispensable:

Aerospace Industry

Precision is critical in aerospace applications. CNC turning parts ensure that components meet stringent safety and performance specifications, thus contributing to the reliability of aircraft and spacecraft.

Automotive Sector

The automotive industry relies heavily on CNC turning parts for producing components such as engine parts, transmission systems, and chassis. The consistency and precision provided by CNC machining are vital for ensuring vehicle safety and performance.

Medical Equipment Manufacturing

In the medical field, the production of surgical instruments and implants demands extreme accuracy. CNC turning parts allow manufacturers to create complex shapes and designs necessary for advanced medical solutions.

Consumer Electronics

From smartphones to home appliances, CNC turning parts are integral in producing the tiny, intricate components that drive modern electronics. The ability to mass-produce these parts with high precision is essential for meeting consumer demands.

The Future of CNC Machining and Innovation

As technology continues to develop, the future of china lathe machine CNC turning parts looks even more promising. Innovations in materials, software, and machining techniques are on the horizon:

1. 3D Printing Integration

Integrating CNC machining with 3D printing technologies can lead to more efficient production processes, allowing for rapid prototyping and custom part manufacturing.

2. Automation and AI

The incorporation of artificial intelligence in CNC operations is set to enhance automation, further reducing human error and improving process efficiency.

Conclusion: Elevating Your Business with Quality CNC Turning Parts

In summary, investing in high-quality china lathe machine CNC turning parts is vital for businesses aiming to enhance their manufacturing capabilities. By partnering with reliable suppliers, companies can tap into the many advantages offered by CNC technology, including cost-effectiveness, customization, and enhanced precision. As the industry continues to evolve, staying informed about trends and innovations will position your business for future success.

For more information or to explore our comprehensive range of CNC machining services, visit Deep Mould today!